Engineered Stone Banned!

Engineered Stone Banned!

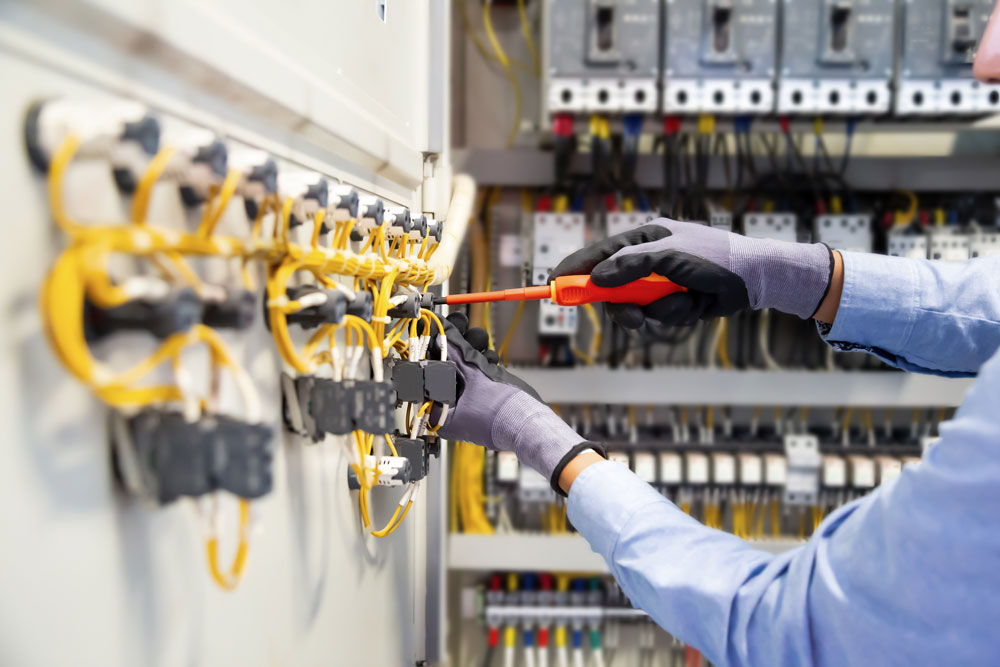

Today we’ll explore electrical safety in the workplace, meeting your duty of care obligations, and demonstrating due diligence. We’ll do this by looking at relevant Work Health and Safety (WHS) legislation, appropriate resources and by implementing a 5WH review of the topic; in other words, we’ll ask ‘Why?’, ‘Who?’, ‘Where?’, ‘What?’, ‘When?’ and ‘How?’ questions.

The 5WH check is a tool used to hit all the main points of a topic, and it’s a sensible way for us to navigate this topic. Specifically, we will look at:

Our goal is to help you know ‘watt’ to do in regards to electrical safety, reduce your ‘charges’, ‘shock’ you with how easy it can be, and leave you feeling ‘ex-static’ with the results - all puns intended. :-)

It’s worth asking if a topic is worth our time? Our approach to electrical safety has life altering and sometimes life ending consequences. How effectively we navigate it also impacts operational costs as well as your ultimate profits and productivity. It’s definitely worth our time.

We won’t labour this issue either. You probably already know the answer. As a business owner or principal, it’s squarely ‘on you’ to ensure your work practices do not affect the health and safety of your workers, contractors you engage, clients and others within your zone of operations. That includes your undertakings on behalf of, or when subcontracted to, another PCBU (person conducting a business or undertaking). If you’re reading this, that probably means you!

As far as jurisdiction is concerned, the 2012 model WHS legislation has been adopted by New South Wales, Tasmania, South Australia, Queensland, the Australian Capital Territory and Northern Territory. As of March 2022, Western Australia remains undecided, and Victoria claims the implementation costs are too arduous.

Electrical hazards are broadly recognised as one of the Big Four of the construction industry (i.e. falls, electrocution, caught-in, and struck-by). Not surprisingly then, the risk of injury from electricity is strongly linked to location and procedures, for example, wet surroundings or cramped spaces.

Electrical safety is most often compromised by the following:

In other words, there are a lot of places where things can go wrong, which is why electrocution is one of the most significant hazards faced on a construction site.

Electrical safety is achieved when electrically induced burns, shocks and electrocution are avoided and secondary risks like fire (also a WHS risk) are averted. Even simple things like double adaptor piggy-backing can cause an overload and a fire.

Foundationally, we can tend to focus on four electrical risk management areas:

For the most part, these policies and practices are simple and easy to implement - once known and supported, but there are many challenges to face.

Commonplace assumptions, restrictions, and applications are at the more straightforward end of WHS practices. These would include assuming wires are lethal and unsafe, restricting actions and repairs to the appropriately qualified, using insulated pins and plugs, and not exposing electrical panels to the rain - don’t laugh, it’s happened.

Beyond this, you have routine and periodic responsibilities, such as electrical test and tagging, maintenance and testing of RCD safety switches, and testing that your electrical circuits and equipment are not overloaded (which involves more than reducing your double adaptors).

Then there are the tasks with significant specificity levels of technical compliance. Examples of this would include Electrical Submains Installation, Pyrotenax Cable Installation, and Testing for De-Energised Electrical Conductors.

So what can you do?

The first thing to realise is that incidents and accidents are treated individually. Areas of accountability and standards operate independently. In other words, your exemplary behaviour in one area isn’t going to cover for slackness in another. In basketball, they say having a sweet jump shot can make up for any weakness elsewhere - but electrical safety isn’t basketball.

Your incident and accident responses must follow the established processes, AND those processes must be fully compliant with safety legislation. This includes immediate reactions regarding first aid and crisis management and comprehensive recording, responding and remediation in response to events.

WHS incidents and accidents are:

This sort of ongoing due diligence can be an arduous process - but that’s where your system comes into play.

Obviously, we’re here to meet that need.

In addition to our comprehensive WHS Management System, and specific SWMS’s that control electrical hazards, it’s worth introducing our Electrical SWMS Pack and Electrical WHS Industry Pack.

Both packs are empowering and diligent - in a ‘doing your due diligence’ sort of way. Step by step procedures are provided so you can refine the pre-written procedures, and you can work with confidence, knowing that the protocols are fully compliant with the Work Health and Safety (WHS) Act 2011, WHS Regulations 2017, AS/NZS 3000:2018 Electrical Installations (Wiring Rules) and any relevant Codes of Practice.

This pack includes 66 Safe Work Method Statements that cover almost every aspect of workplace electrical safety. You’ll find the Electrical SWMS Pack here.

As with all our resources, they’re available for instant download and easy customisation to your projects and worksites.

Financially, this is a ‘bright spark’ strategy (another dad joke) because the pack represents a 60% discount off the cumulative purchase price. The bundle price is just $1,690.00 + GST.

As our most comprehensive electrical safety management system, this pack was created to equip you with an effective electrical WHS system, while also providing a swathe of electrical specific and general SWMS. This is worthy of a focused look and you can find the pack here.

At just under $2,500 you’d be right to have high expectations - but you’ll also find them well met! You’ll also save $700 on the cost of purchasing them individually.

Conveniently divided into six parts, the pack includes 66 Safe Work Method Statements and 110 policies, registers, procedures, charts, plans, agreements, checklists, forms and non-SWMS templates (at last count - because we’re constantly looking to improve) and An Introductory Guide to Workplace Safety.

The six focus areas covered are:

As with all our products and solutions:

Also, don’t forget that we regularly create bespoke packages to meet specific needs.

So, how’d we do? Do you know ‘watt’ to do? Feeling ‘shocked’ by how much our resources can help? Feeling ‘ex-static’ with the possibilities? (Or are my dad-jokes ‘sparking’ a groan).

Either way, know that we don’t joke about when it comes to resources that save lives, reduce costs and ensure your peace of mind. We’ve proven it is possible to mitigate electrical hazards and prevent dangerous incidents and accidents - but it’s not all easy, and it’s certainly not all obvious. That’s why we’re here. Call 1800 304 336 and we’ll make a start on exploring your needs, options and possibilities.